The Welding Oscillator Tractor is used to apply vertical or circumferential flux-cored arc welding (FCAW) on steel tanks or pipes. Available in two options: a) Model 3000 applies FCAW on vertical seams on API Tanks up to 3,000 mm in length or pipes over 1,000 mm in diameter, and b) Model 150-1000 applies FCAW on pipes from 150 up to 1,000 mm in diameter. Available power source at extra cost. Welding Oscillator Tractor, also known as Welding Carriage, Welding Automation Carriage, Welding Oscillator Carriage and Track Welding Carriage with Oscillator.

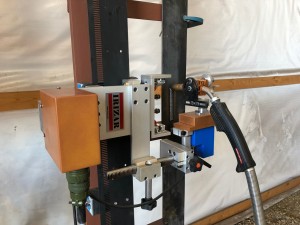

Welding Tractor Model 3000

Apply vertical or circumferential Flux Cored Arc Welding (FCAW). For API Field Erected Tanks, we recommend installing the tractor on our Motorized Basket. This Self-Propelled Buggy provides quick access to vertical seams without the need for scaffolding.

- Apply: 1) Verticals: Up to 3,000 mm. 2) Pipe OD > 1,000 MM

- On/Off Switch

- Quick Clamping Torch Holder for welding gun

- Forward/Reverse Travel Switch

- Interface Welding Machine Switch

- Variable Speed Knob: From 50 to 1040 mm/minutes

- Torch Adjustment: Up/Down: ±50 mm, Left/Right: ±100 mm, Angle: ±45 degrees.

- Left/Right Stroke: ±17 mm

- Oscillation Angle: ±10 degrees

- Oscillation Pattern Selection Knob: Five types

- Power Supply: AC 110 V, 50/60 HZ, single phase

- Flexible Rail Track: Two of 1.6 m each, plus twelve magnets

- Magnets: Twelve

- Packing dimensions (mm):

- Tractor: 580 (L) x 250 (W) x 345 (H) @ 11 kgs

- Tracks: 1,600 (L) x 50 (W) x 50 (H) @ 8 kgs

- Magnets: 500 (L) x 200 (W) x 200 (H) @ 25 kgs

- Total Weight: 44 kgs

Full set, ready to work

- Oscillator Tractor

- Lincoln Wire Feeder

- Lincoln Power Source

- Lincoln Welding Head and Controller

- Lincoln Welding Gun. 15 ft. cable

- Drive wire Rolls: 035/045 Solid, 035C, 045C, 052C & 1/16″C

Not included: Welding Cables, Control Cables and Lincoln Contact Tips

Welding Tractor Model 150-1000

- Apply: Circumferential seams on pipe diameters from 150 mm up to 1,000 mm

- On/Off Switch

- Quick Clamping Torch Holder for welding gun

- Forward/Reverse Travel Switch

- Interface Welding Machine Switch

- Variable Speed Knob: From 50 to 700 mm/minutes

- Torch Adjustment: Up/Down: ±50 mm, Left/Right: ±100 mm, Angle: ±45 degrees.

- Left/Right Stroke: ±17 mm

- Oscillation Angle: ±10 degrees

- Oscillation Pattern Selection Knob: Five types

- Power Supply: AC 110 V, 50/60 HZ, single phase

- Flexible Rail Track: 3.7 m of rail included. Use only on pipe diameters from 300 to 1,000 mm

- Magnets: NA

- Packing dimensions (mm):

- Tractor: 410 (L) x 360 (W) x 22 (H) @ 22 kgs

- Tracks: 540 (L) x 420 (W) x 140 (H) @ 5 kgs

- Magnets: NA

- Total Weight: 27 kgs

Full set, ready to work

- Oscillator Tractor

- Lincoln Wire Feeder

- Lincoln Power Source

- Lincoln Welding Head and Controller

- Lincoln Welding Gun. 15 ft. cable

- Drive wire Rolls: 035/045 Solid, 035C, 045C, 052C & 1/16″C

Not included: Welding Cables, Control Cables and Lincoln Contact Tips

Notes:

Our company recommends consulting a Certified Welding Engineer (CWEng) to design the welding procedure in accordance with the relevant national and provincial codes and standards. In Canada, CWEngs are certified by the Canadian Welding Bureau (CWB). In contrast, in the USA, they are accredited by the American Society of Mechanical Engineers (ASME), the American Welding Society (AWS), and the American Petroleum Institute (API), among other prestigious organizations worldwide. A CWEng is responsible for designing and selecting the appropriate welding parameters, which include plate beveling, wire and flux specifications, amperage, voltage, and welding speed, among other factors.

Irizar does not offer training, as the machine is straightforward to operate. Certification is required for this trade, meaning the operator holds a certification as a journeyperson. Irizar rental facility is available in Wetaskiwin, AB, Canada, where customer welder operators can familiarize themselves with the equipment and obtain coupons for qualifying Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), and Welder Qualification Tests (WQT). Otherwise, we recommend purchasing the machine in advance and making it work in your shop before setting it up on the jobsite.

Delivery Time:

Within Canada: Three to five business days

USA & US-Mexican border: One week

Latino America: Four weeks

World-Wide: Five to six weeks